Bottom Loading Arms

Bottom loading offers benefits which cannot be achieved with top loading designs. Taking place on the ground, it’s inherently safer for the operator and also

allows for simultaneous loading of several tank compartments, increasing speed and efficiency of loading. Bottom loading is easily adaptable to vapour recovery

systems.

Bottom Loading Arms

API Recommended Practice (RP) 1004

Specified below are the API Bottom Loading options that Soliflo manufactures under licence from Emco Wheaton.

- All loading arms are manufactured under licence and to Emco Wheaton specifications using only original Emco Wheaton components and test procedures.

All fabrication is performed by ASME IX coded welders and a high quality marine grade paint system adopted for the carbon steel components.

- Soliflo is an ISO 9001:2015 accredited company and all loading arms are subjected to a 10% radiographic inspection of all wetted butt welds, hydrostatic pressure

test at 1.5 x design pressure and a 0.5 bar air leak test as a minimum. All materials are traceable and 3.1B certificates will be supplied for all wetted components.

- The equipment falls under SEP of the European Pressure Directive and South Africa’s SANS 347:2010 standards, where required additional surveillance by an approved

AIA can be included at an additional cost, should a client’s specific requirements need to be adhered to. For instance, some customers, refineries in particular, work on a

minimum standard of Category II Module G.

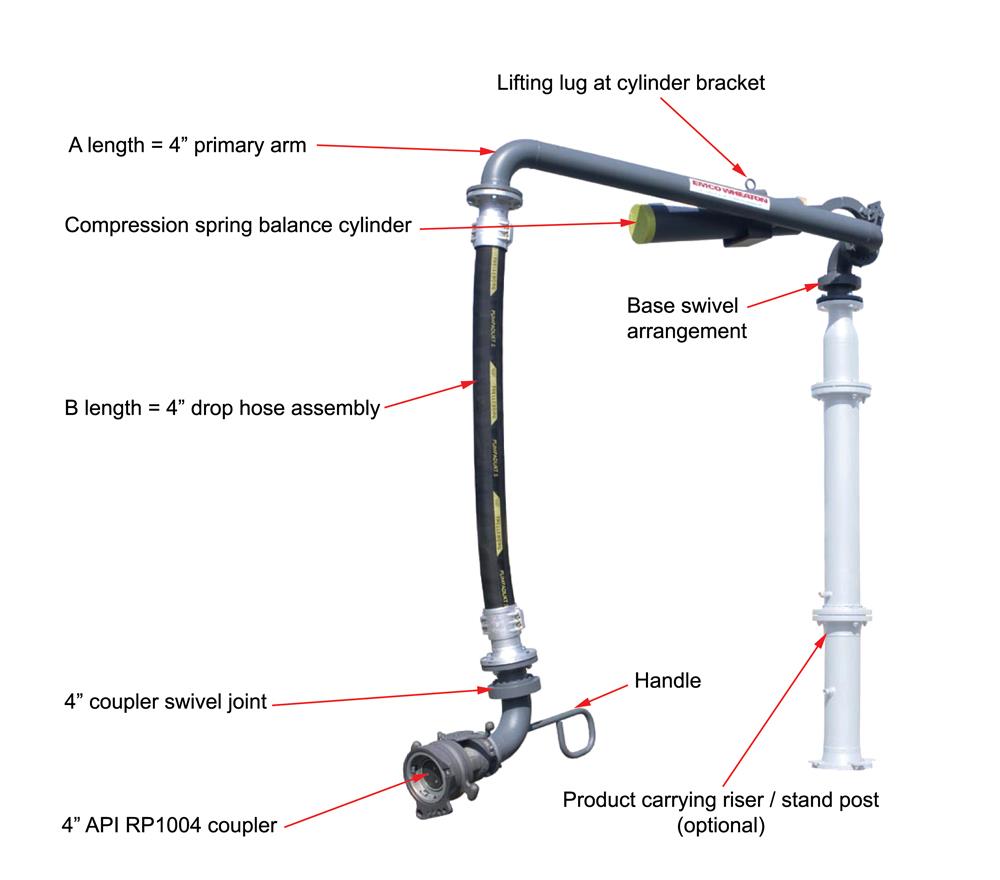

General Equipment Descriptions:

The major / main components of loading arm assembly are as per the diagram.

There are a number of options relating to components which will affect the price structure.

These will be clearly described and detailed in the quotation document.

Emco Wheaton Model E2852 API Bottom Loading Arm

Locally manufactured

This loading arm is designed, manufactured and supplied to the highest possible standards for which Emco Wheaton are renowned.

The swivel joints are all supplied with deep flame hardened ball races and polished stainless steel seal faces for higher integrity and longer seal life.

Emco Wheaton Model E2852 LIGHT API Bottom Loading Arm

Locally manufactured

This loading arm is designed, manufactured and supplied to meet the standards of certain of our competition. The swivel joints are supplied with mild steel seal faces and the coupler swivel joint is of a cast aluminium construction.

Emco Wheaton Model EB2852 KONNEKT API Bottom Loading Arm

Locally manufactured

This loading arm is designed, manufactured and supplied to meet the standards of certain of our competition. The swivel joints are supplied with mild steel seal faces and

the coupler swivel is of a cast aluminium construction.

This version of arm features cast iron and aluminium bolt-on assemblies throughout. Less fabrication is therefore required, the advantage being the extremely short delivery time of 4 - 5 weeks from approval of drawings.

Emco Wheaton Model E2701 Long Reach API Bottom Loading Arm

Locally manufactured

This is a long reach version of the bottom loading arm, normally used for the transfer of refined hydrocarbons at large and busy terminals.

It’s also utilised for vapour recovery purposes whereby it has a reach and configuration allowing connection to either the side or rear vapour connections of a tanker.

Specifications for API Bottom Loading Arms manufactured and supplied by Soliflo:

FEATURES

| FEATURES |

E2852 Standard |

E2852 LIGHT |

E2852 KONNEKT |

E2701 Long Reach |

| D2000 Base Swivel Joint Arrangement |

|

|

|

|

| D2000 Coupler Swivel Joint |

|

|

|

|

| SEC Cast Aluminium Coupler Swivel Joint |

|

|

|

|

| Stainless Steel Swivel Joint Seal Faces |

|

|

|

|

| Flame Hardened Ball Races |

|

|

|

|

| Compression Spring Balance Cylinder |

|

|

|

|

| 16 bar Suction & Delivery Hose |

|

|

|

|

| Marine Grade Coating System |

|

|

|

|

| Fully Welded Construction |

|

|

|

|

| Hydrostatic Test |

|

|

|

|

| Air Leak Test |

|

|

|

|

| Radiography (10%) |

|

|

|

|

| 3.1B Material Certificates |

|

|

|

|

| 4 - 5 Week Delivery Time |

|

|

|

|

| 10 - 12 Week Delivery Time |

|

|

|

|

Emco Wheaton E2386 Bottom Loading Station

Emco Wheaton E2386 Bottom Loading Station

Our E2386 loading arm is especially designed to load products where vapour return is necessary.

It is suitable for the bottom loading / unloading of road or rail tankers with flange connection or coupling.

These loading arms have a long reach and are suitable for applications where tanker connection flange cannot be accurately positioned.

For connection pipes with high weight, the loading arm can be designed with a special 6 swivel configuration with parallel bar and gas spring for balancing the weight of the connection pipe.

Due to the robust and high quality design of the swivel joints, and the precise loading arm balancing, the loading arm is very easy to handle.

Emco Wheaton E2824 to E2839 - Standard Bottom Loading Arms

Emco Wheaton E2824 to E2839 - Standard Bottom Loading Arms

This type of loading arm is especially designed to load mineral oil or chemical products and is suitable for the bottom loading / unloading of road or rail tankers.

The loading arm has a long reach and is suitable for applications where the tanker connection flange cannot be accurately positioned.

Due to the robust and high quality design of the swivel joints, and the precise loading arm balancing, handling of the loading arm is effortless.

Emco Wheaton E2852 and E2701 - Bottom Hose Loading Station

Emco Wheaton E2852 and E2701 - Bottom Hose Loading Station

Locally manufactured

The Bottom Hose Loading Station enables efficient loading of tank trucks with simultaneous loading of up to five products plus a vapour arm.

The loading station is designed to enable a totally flexible operation with unrestricted cross-over of all arms.

The loading arms are equipped with our API Couplers.

Our carbon steel swivel joint has a flame hardened ball race to ensure a long service life.

Emco Wheaton LNG Bottom Loading Arm

Emco Wheaton LNG Bottom Loading Arm

This loading arm is especially designed to load LNG products and is suitable for the bottom loading / unloading of road or rail tankers.

The loading arm has a long reach and is suitable for applications where tanker connection flange cannot be accurately positioned.

Due to the robust and high quality design of the swivel joints, and the precise loading arm balancing, handling of the loading arm is effortless.

The design of the stainless steel swivel joints are based on the reliable D2000 and are also equipped with an interchangeable bearing module.

The primary and secondary product seal enables the operator to monitor leakage during the whole operating time of the loading arm. In addition, the ball raceway

can be purged with dry gas and the swivel joints are designed to meet the requirements of the OCIMF.

Emco Wheaton EB2852 - World Bottom Hose Loader

Emco Wheaton EB2852 - World Bottom Hose Loader

The EB2852 World Bottom Hose Loader is designed for the bottom loading and unloading of road or rail tankers with all types of fuel.

Tanker side connection is achieved with a 4” API coupler. The loading arm dimensions are designed to cover the complete API connection area.

A bottom loading station can consist of up to 5 product arms. The design allows unrestricted crossover of all arms. A separate loading arm for vapour

recovery completes the installation.

Our carbon steel swivel joint has a flame hardened ball raceway to provide long service life.

For the API Couplers, various options are available:

- New J0452 (10 bar or 16 bar), optional integrated pump with filter element, if required.

- Perolo CAMSEC Coupler (10 bar) with integrated check valve, if required.

- J0451 (6 bar), safety interlock feature

- K2 & K2P (16 bar), zero spillage by pumping mechanism

- J0100 (16 bar), high pressure version; with integrated check valve, if required